How does Jumper Technology reconstruct a new landscape of clean and low-carbon coal with the new generation of coal-fired power transformation and upgrading?

With the issuance of the "Implementation Plan for the Special Action on Upgrading the New Generation of Coal-fired Power Plants (2025-2027)", it is clear that the coal-fired power industry will focus on "deep peak regulation, fast regulation, strong support, wide load, high resilience, and low emissions" over the next three years. Particularly in terms of clean carbon reduction, even stricter requirements have been set for coal-fired power plants:

New units need to reserve conditions for low-carbon transformation.

Existing units are encouraged to implement low-carbon transformations.

The carbon emission level per kilowatt-hour of pilot demonstration units should be reduced by 10%-20% compared to similar units in 2024.

Against this backdrop, Clean processing of coal at the front end is becoming increasingly important. Jumper Technology's intelligent coal gangue picking equipment, with its efficient and low-carbon technological advantages, has become an important driving force in promoting clean coal carbon reduction.

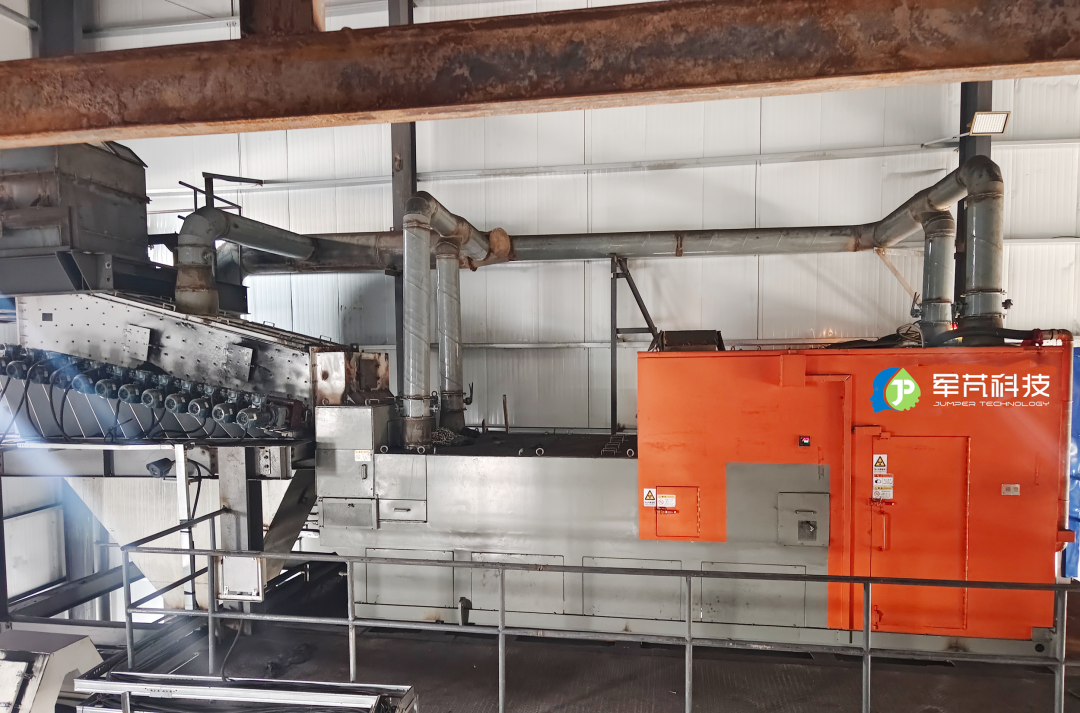

Jumper Intelligent Coal Gangue Picking Equipment

Gangue in coal is one of the key factors affecting combustion efficiency and carbon emissions. Traditional wet coal preparation processes have problems such as high water resource consumption and high energy costs, and the resulting "coal slime" by-product poses environmental pollution risks.

Jumper Technology's intelligent coal gangue picking equipment is a new generation of intelligent block coal gangue picking equipment based on advanced imaging and artificial intelligence technology. This equipment uses a spectral imaging system to acquire material characteristics, automatically analyzes and identifies coal and gangue, controls high-pressure air to blow the target, achieving "early gangue removal and refined coal quality improvement", laying the foundation for low-carbon emissions in subsequent combustion stages.

Dry Picking Drives Energy Efficiency Upgrades

Unlike traditional processes that rely on water media, Jumper Technology's intelligent coal gangue picking equipment uses a unique millisecond-level JPSUPER® computer algorithm and artificial intelligence technology, a high-definition resolution image acquisition device, and imported high-speed spray valve devices. The picking process does not require water or media; the processing capacity of a single unit can reach up to 600 tons/hour (Intelligent coal gangue picking equipment picking data), picking particle size covers +10mm-300mm ,gangue removal rate over 98% ,effectively reducing the load and energy consumption of subsequent operations and lowering operating costs.

After a coal gangue project in Shaanxi introduced Jumper's intelligent coal gangue picking equipment, production capacity increased to 50-300 tons/hour, the gangue-to-coal ratio after picking is less than 2%, the gangue removal rate exceeds 98%, and the coal picking cost is as low as 2 yuan per ton. 。

Restructuring the Clean Coal Chain

As an innovative technology in the ore pre-selection stage, intelligent dry selection is of great significance in reducing the carbon emissions of the entire life cycle of coal.

Improving gangue removal capacity and efficiency, reducing the ineffective transportation of gangue, improving coal recovery rate, and simultaneously reducing energy consumption in washing, transportation, and other links to reduce carbon emissions.

After picking, the ash content and sulfur content of raw coal can be effectively reduced, and the calorific value of coal can be improved, thereby reducing the transportation load and reducing the emission of pollutants during coal combustion, alleviating air pollution.

Establishing a clean production paradigm of precise material separation, moving pollution control from end-of-pipe treatment to source control.

In the process of the coal-fired power industry transforming from a "guaranteed supply ballast" to a "green regulator", the innovation of front-end picking technology has become an indispensable link. Jumper Technology, with intelligent coal gangue picking equipment as its core, promotes the upgrading of coal picking to high efficiency, low carbon, and intelligence, not only in line with the "clean carbon reduction" main line proposed in the "Plan", but also providing long-term value for the industry's carbon reduction and efficiency improvement from the source of the industrial chain.

In the future, with the deepening of low-carbon transformation of coal-fired power plants, intelligent picking may become standard equipment for the green transformation of coal-fired power plants, helping to optimize China's energy structure and achieve high-quality implementation of the "dual carbon" goals.

Recommended information