Intelligent ore dressing system/information system

Leading internet and information technology solutions

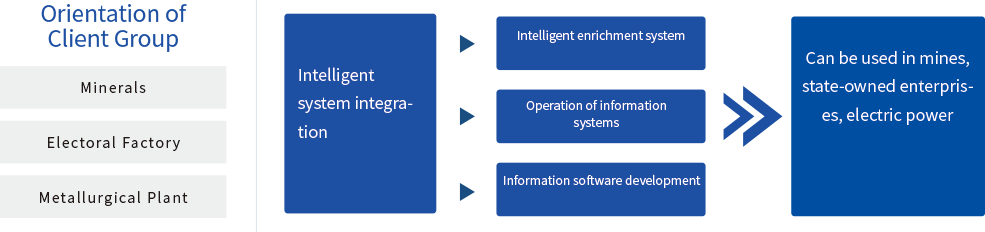

Jumper Technology relies on the IT industry and is supported by software technology. It specializes in software development, building intelligent engineering, weak current engineering, network engineering, security engineering, and computer information system integration design, construction, maintenance, and services. The systems developed and designed by the company are widely used in mining, government, state-owned enterprises, and power projects.

Intelligent Ore Selection System

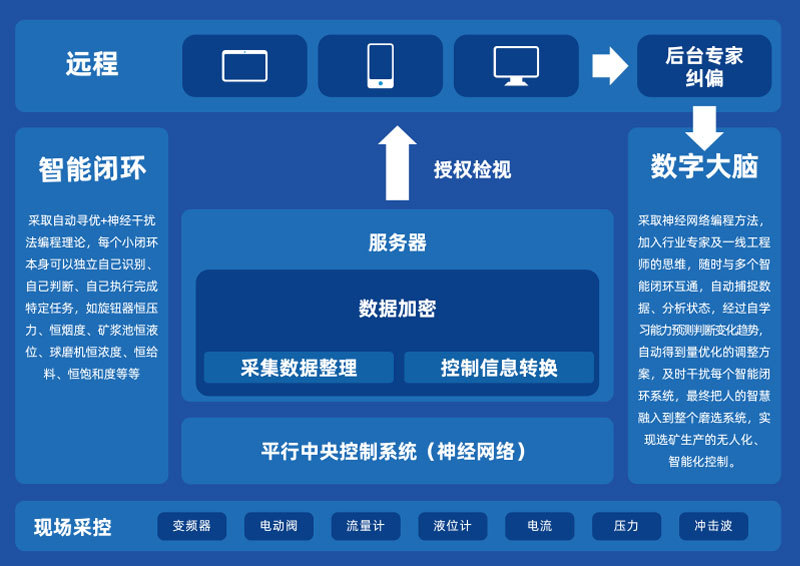

Junpeng's intelligent monitoring and control system for ore selection is an intelligent monitoring and control technology for ore selection that has evolved from basic automation combined with cloud computing and big data. Due to the characteristics of the variability of the ore hardness and the randomness of the particle size composition in the ore selection process, the intelligent ore selection technology performs real-time detection of the operating status of various equipment on site in the ore selection plant, and performs big data intelligent analysis to obtain the current ore hardness and particle size composition dynamics, and timely issues reasonable control instructions to make up for the shortcomings of conventional ore selection automation.

Intelligent ore selection = digital brain + neural network + intelligent closed loop

Mining industry service content

Smart Mine Construction

5G+ Smart Mine Construction

Utilize the 5G network to achieve intelligent interconnection between various equipment and platforms in the mine selection plant and mining area. Leveraging the high speed, low latency, and large connectivity of 5G, combined with digital modeling, 3D display, data analysis, and virtual simulation technologies with mine management, a widely distributed and highly usable decision support system is formed, achieving digital, information, and intelligent control of geological measurement, resource management, mining production, ore processing, transportation, and warehousing, resulting in a modernized mine.

Safety Informationization

Mine 3D map information system, mine big data platform.

Mine Integrated Automation System

Industrial television, central control dispatching center and control system, intelligent equipment control system, mine personnel management system, mine wireless coverage, mine underground communication system, GPS vehicle intelligent scheduling management system, intelligent inspection system.

Remote control

Mine truck autonomous driving/assisted driving, single-vehicle intelligent scheme and parallel driving scheme

Unmanned mine trucks are managed and comprehensively dispatched by the parallel unmanned mine control center. The mine trucks and the center interact bidirectionally and parallel intelligently, and remote takeover is performed in case of emergencies.

Remote control type, remote control/assisted driving of mining equipment

Remote manual operation of excavators, bulldozers, power shovels, etc., on-site video transmission from the mining area, and remote operation of equipment by the driver.

Remote driving of underground transportation mine cars

5G radio frequency equipment is installed on the tunnel walls, and periodic antenna coverage is achieved to achieve 5G signal coverage in the tunnel, supporting remote driving of mine cars.

Machine Vision

AI Smart Coal Mine Business Monitoring

Push intelligent AI applications to various edge mine points to achieve real-time monitoring and AI analysis of underground sensor data, water exploration operations, belt conveying, and violations, significantly improving the safety production level of mine points.

Open-pit mine drone inspection, mine geological surveying and mapping

Combined with AI image recognition, daily inspections are carried out in the mining area; during blasting, intelligent warning is implemented in the blasting area, and after automatically identifying people, animals, and mine cars, timely warnings are issued. After the drone aerial photography collects data, it is transmitted back to the offline workstation via the 5G network for preprocessing. The preprocessed data is sent to the 3D modeling server to update the terrain and surface information in a timely manner.

Mining Equipment Data Acquisition

In the short term, due to the constraints of 5G module cost and power consumption, it is not yet possible to directly access sensors. Data needs to be aggregated and preprocessed through PLC or industrial gateways, and then connected to the 5G network using CPE or industrial gateways with embedded 5G modules.

AR Assistance

5G-based mine AR application

Information System Operation and Maintenance

Provide value-added services such as data center machine room operation and maintenance, upgrades, and training, as well as software maintenance services such as databases and middleware. The company has a dedicated spare parts/spare parts warehouse and first-line and second-line system support organizations to ensure that customers can get the fastest response and solution in the event of system failures.

Information Software Development

The company has 20 years of product R&D experience and has always adhered to independent intellectual property rights technology. It has strong and continuous innovation capabilities in scientific research and development.

Automated Office System

Training Information System

Enterprise Information Management System

Intelligent Power Distribution Information Processing System