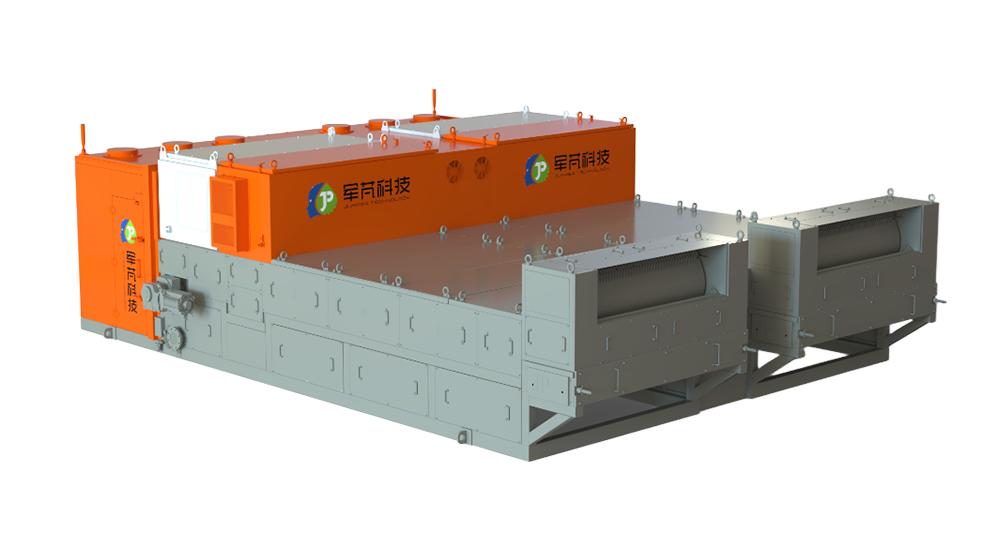

JPXRT Coal Gangue Sorting System

Share to

Product Parameters

JPXRT2000

| Main equipment weight | 12.5t |

| Main equipment dimensions | 8410×3640×2460mm |

| Mainframe conveyor belt width | 2000mm |

| Processing particle size | +10-300mm |

| Power consumption | 25kw/h |

| Working power supply | 380V(AC) |

| Control system power supply | 220V(AC) |

| Capacity | 80-300t/h |

JPXRT2000M

| Main equipment weight | 23.5t |

| Main equipment dimensions | 8200×6400×2450mm |

| Mainframe conveyor belt width | 4000mm |

| Processing particle size | +10-300mm |

| Power consumption | 50kw/h |

| Working power supply | 380V(AC) |

| Control system power supply | 220V(AC) |

| Production capacity | 160-600t/h |

Application Scenarios

| Suitable for gangue removal in raw coal preparation workshops | Suitable for pre-gangue removal in coal transportation stations | Suitable for gangue removal in the renovation of old mine coal buildings |

| Suitable for coal and gangue picking in arid and frigid regions | Suitable for pre-treatment of materials in coal washing plants |

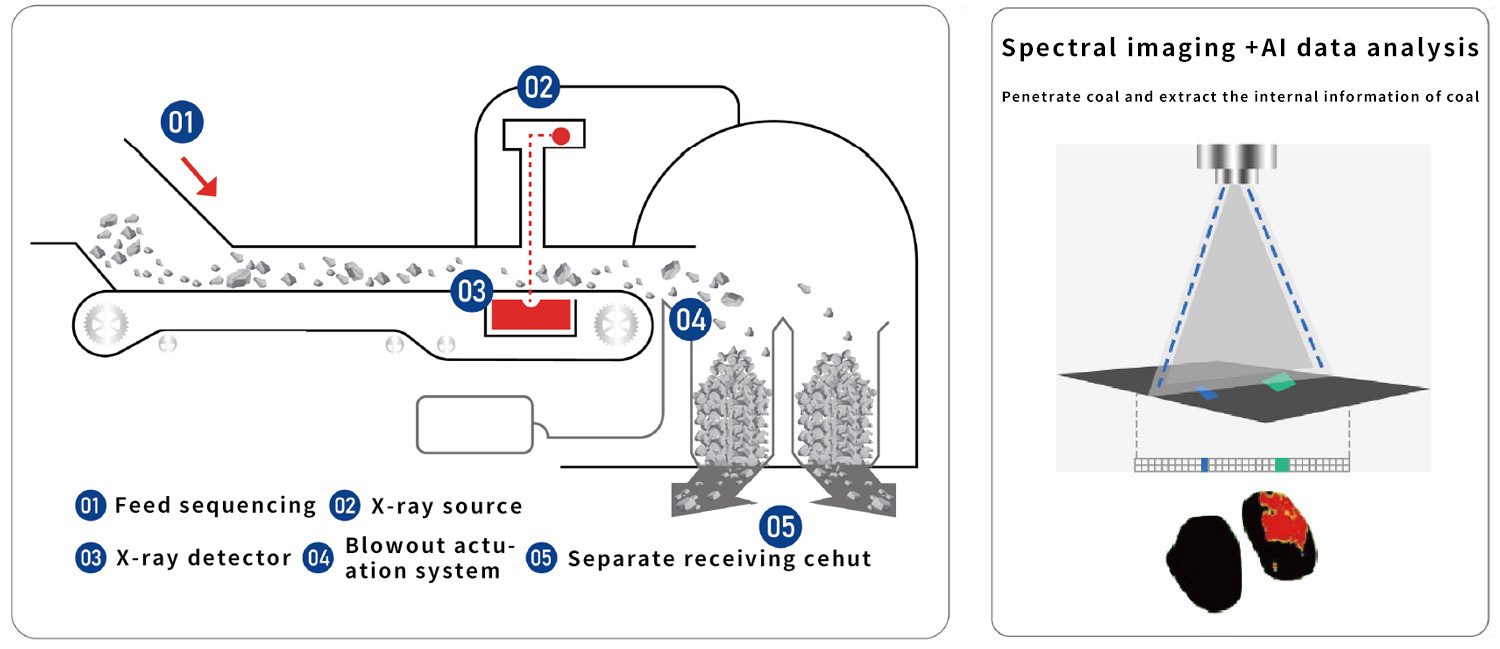

Picking Principle

Application Process

Raw coal mined from coal mines is transported to the coal preparation plant (or coal yard), screened and sorted by size using a roller screen, and then fed into the picking machine via a vibrating feeder for coal and gangue separation. The separated gangue is discharged via a conveyor belt to the gangue filling site, and the coal is transported via a conveyor belt to the coal bin.

Product Value and Significance

- Reduces the transportation volume of gangue, saving transportation costs;

- Effectively reduces the amount of gangue entering the subsequent system, improving the processing capacity of the existing washing and selection system;

- Effectively reduces gangue crushing energy consumption and the generation of secondary coal slime, reducing wear and tear on equipment, pipelines, and chutes, benefiting coal slime picking and coal slime water treatment, and reducing the consumption of flotation agents and flocculants;

- Effectively reduces the load and energy consumption of subsequent operations, lowering operating costs.

Core Value

|

20,000,000-50,000,000 |

15,000,000 |

2/3 |

3/4 |

2-4 yuan/t |

|

Water Resource Savings |

Reduced Subsequent Coal Preparation Energy Consumption |

Improved Coal Preparation Plant Capacity |

Supports the National Dual Carbon Strategy |

Reduced Chemical Usage |

Product Advantages

Advantage OneHigh Intelligent Picking Efficiency Intelligent picking technology can improve gangue removal capacity and efficiency, reduce ineffective gangue transportation, increase lump coal recovery rate, release the production capacity of coal preparation plants and mines, and reduce subsequent production costs. |

Advantage TwoAI Technology for Precise Screening Utilizes unique millisecond-level JPSUPER® computer algorithms and artificial intelligence technology, with a gangue content in coal <1%. |

Advantage ThreeHigh-Efficiency Collection with Wide Particle Size Range Employs high-resolution image acquisition devices and imported high-speed spray valve devices, with a gangue ejection rate ≥98% and a picking particle size range of +10-300mm. |

Advantage FourHigh Safety Standards in Application Designed and manufactured independently in accordance with national standards, key components are selected from internationally renowned brands, with explosion-proof and coal mine safety certifications, and a dust removal system. |

Advantage FiveWaterless Picking for Greater Environmental Protection Physical sorting, no other medium required, only electricity is needed, no water picking, energy saving and emission reduction, avoiding environmental pollution. |

Advantage SixMore Intelligent Operation and Use Realizes one-button start-up, one-button coal selection, etc., only one operator is needed for equipment operation, reducing labor and improving enterprise economic benefits. |

Category:

Intelligent picking

Keyword:

Jumper Technology

Product Consultation

Note: Please leave your contact information, and our professionals will contact you as soon as possible!