JPXRT Intelligent Ore Sorting System

Share to

Product Parameters

JPXRT1400

| Main equipment weight | 10t |

| Main equipment dimensions | 8200×2310×2450mm |

| Processing particle size | +12-200mm |

| Processing capacity | 40-60t/h |

| Working power supply | 380V(AC) |

| Rated power | 20KW |

| Control system power supply | 220V(AC) |

| Belt conveyor speed | 3m/s |

| Belt width | 1400mm |

| Minimum scanning resolution | 0.1mm |

| Working humidity | <95%(no condensation) |

JPXRT2000

| Main equipment weight | 11.5t |

| Main equipment dimensions | 8200×2900×2450mm |

| Processing particle size | +12-200mm |

| Processing capacity | 80-120t/h |

| Operating power supply | 380V(AC) |

| Rated power | 25KW |

| Control system power supply | 220V(AC) |

| Belt conveyor speed | 3m/s |

| Belt width | 2000mm |

| Minimum scanning resolution | 0.1mm |

| Operating humidity | <95%(no condensation) |

JPXRT2000P

| Main equipment weight | 15t |

| Main equipment dimensions | 8200×3900×2450mm |

| Processing particle size | +12-200mm |

| Processing capacity | 120-160t/h |

| Operating power supply | 380V(AC) |

| Rated power | 30KW |

| Control system power supply | 220V(AC) |

| Belt conveyor speed | 3m/s |

| Belt width | 3000mm |

| Minimum scanning resolution | 0.1mm |

| Operating humidity | <95%(no condensation) |

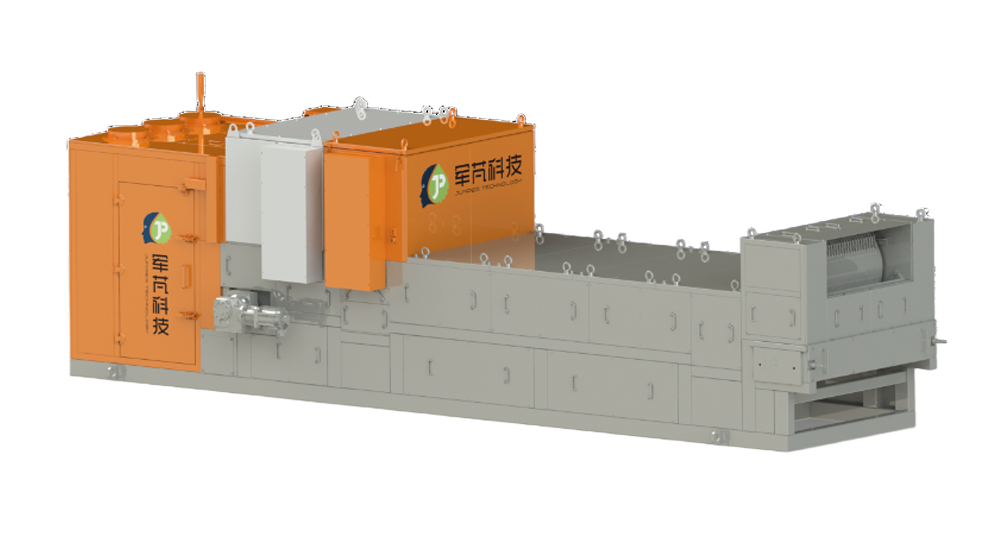

Picking Principles

Ore is transported via conveyor belt to the X-ray detection area, where the detection components perform spectral detection on the ore. Based on spectral imaging and material identification, data is transmitted to the core processor for qualitative and semi-quantitative analysis. Using Jumper's unique millisecond-level JPsuper@ computer algorithm, the detected ore is judged as concentrate or tailings; the sorting is achieved through a jetting execution system, using a high-speed air gun for precise impact, blowing tailings into the tailings receiving tank and concentrate into the concentrate receiving tank, achieving effective separation and sorting of ore and waste rock.

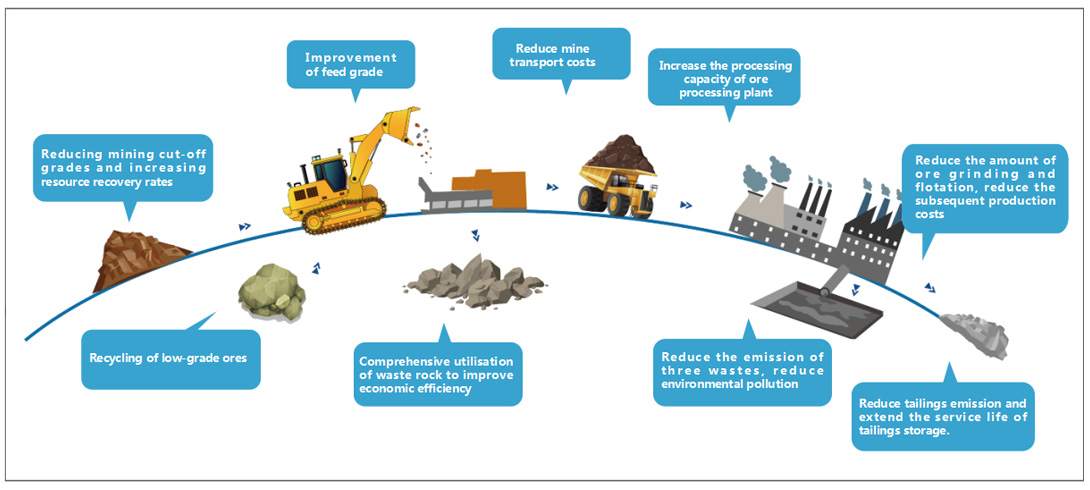

Core Value

Leading the new direction of intelligent ore picking

Key Technology

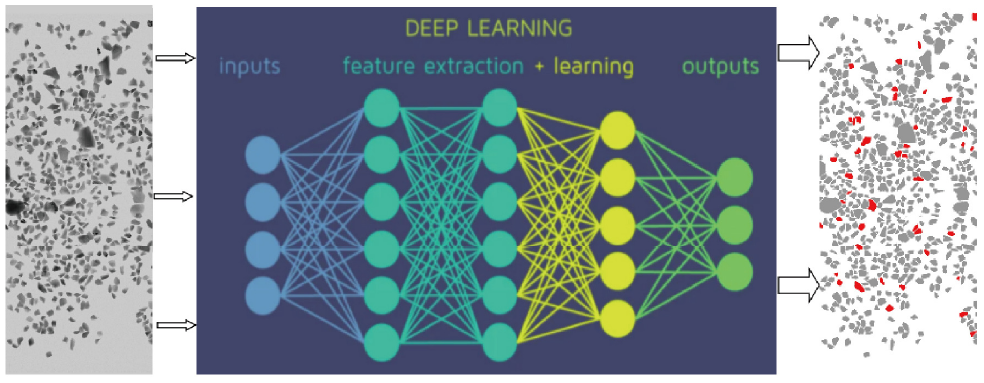

- Using unique millisecond-level JPSUPER® computer algorithms and artificial intelligence technology, it efficiently identifies and sorts ore, ensuring high-speed, stable, and accurate operation of the detection conveyor belt.

- Unique PC-based Huawei AI and FPGA control and computing platform, ensuring data throughput, real-time computing, and control accuracy.

- Using deep learning and Ascend computing technology for big data computing and sample aggregation, ensuring the real-time requirements of block ore target inference calculation, high-speed and accurate processing of detection data, and online learning optimization according to different ore properties.

- Continuously collecting data on various ore samples of non-ferrous metals, forming a unique database and laying the foundation for the research and development of similar ores with similar properties.

Leading Advantages

Efficient and precise, fully intelligent, highly adaptable, safe and reliable

High-precision identificationIntegration of advanced detection technologies such as X-ray multi-dimensional, multi-spectral, and multi-sensor detection, enabling high-resolution, high-precision, and accurate identification of ore and waste rock. |

Intelligent RemoteIntelligent control and remote operation of the entire single-machine picking process, remote fault diagnosis, and remote system upgrades. |

High-throughput pickingSingle-machine ore picking processing capacity of 150-500 tons/hour. |

Wide particle size selectionSingle machine can simultaneously process ore particle sizes of +12mm-200mm. |

Natural background protectionSingle-machine X-ray ionizing radiation protection dose, annual absorbed dose per person ≤2mSv, far below the national standard of 20mSv, equivalent to natural background. |

|

Detection Technology

Photoelectric pre-selection utilizes the physical mechanism between the spectrum and the ore, detecting the mineralogical characteristics of the ore through photoelectric sensors and converting them into data that can be stored by a computer; then, using certain mathematical calculation methods, the ore dataset is classified into target ore dataset and non-target ore dataset, and then separated through specific electromechanical actuators and control methods.

| Spectral Name | Spectral Wavelength Range | Detection Principle |

| Near-infrared | 0.75~2.5nm | Absorption and reflection effects of special mineral components |

| Visible light | 400~750nm | Color, texture, and morphology of minerals |

| Near ultraviolet | 200~400nm | Fluorescence effect of special mineral components and structures |

| X-ray | 0.1~10nm |

1. Characteristic X-rays (XRF) generated by the outer electron transitions of mineral atoms 2. Photoelectric effect and Compton effect (XRT) of mineral atoms |

| γ-ray | 0.005~0.17nm | Photoelectric effect where mineral atoms' electrons are ionized |

Category:

Intelligent picking

Keyword:

Jumper Technology

Product Consultation

Note: Please leave your contact information, and our professionals will contact you as soon as possible!