Trillion-scale coal washing and selection blue ocean! Jumper Technology empowers the entire process of intelligent washing and selection

In 2019, the National Energy Work Conference elevated coal to a new height and position as the "bottom-line guarantee" of national energy security.

Characteristics of China's Energy Resources: Abundant coal, scarce oil, and limited natural gas 。

Proven Coal reserves account for 90% of China's fossil energy reserves and 33.8% of the world's coal reserves.

Data Source: CCTD China Coal Market Network, "Clean and Efficient Utilization of Coal is the Fundamental Way Out"

In 2023, China's raw coal production reached 4.71 billion tons year-on-year growth of 3.4% 。

Data Source: China Coal News, "Annual Coal Production Exceeds 4.7 Billion Tons, What Does It Mean?"

In 2023, coal consumption increased by 5.6% and accounted for 55.3% of total energy consumption.

Data Source: China Coal News, "Annual Coal Production Exceeds 4.7 Billion Tons, What Does It Mean?"

China's total coal production and consumption rank first in the world, and coal still plays a dominant role in its energy structure.

01 A trillion-yuan coal washing and selection market with huge potential

Washing and selection is an indispensable link in coal processing. In 2022, the main business income of China's coal mining and washing and selection industry reached 4072.939 billion yuan an increase of 716.521 billion yuan compared to 2021, a year-on-year increase of 21.35% (Data Source: Wu Can, "2023 Edition Report on the Current Situation and Development of Coal Mining and Washing and Selection Industry").

At the same time, under the background of the "dual carbon" goals, China's coal washing rate has shown a significant upward trend. According to the "China Energy Big Data Report (2021) - Coal Chapter," in 2020, China's raw coal washing rate reached 74.1% an increase of 8.2 percentage points compared to 2015. However, compared with developed countries (coal washing rate exceeding 90%), there is still considerable room for improvement.

In recent years, in order to improve the coal washing rate, reduce energy consumption, and reduce emissions, the government has gradually increased its support for washing and selection equipment and technologies. With multiple favorable factors, the washing and selection equipment industry is ushering in a new blue ocean of development.

02 Jumper Technology's Intelligent Coal Sorting and Selection

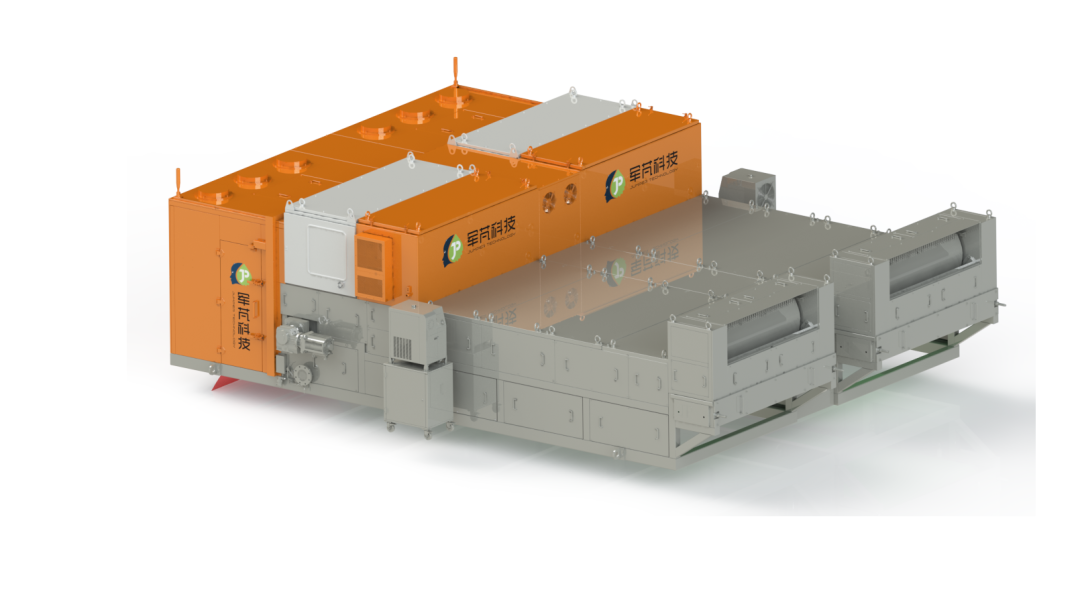

Jumper Technology firmly grasps the market opportunities, is committed to green and efficient mineral sorting, and continuously makes breakthroughs and innovations, especially the independently developed intelligent coal and gangue sorting machine, which has broken through the century-old water washing technology and achieved more efficient, environmentally friendly, accurate, and intelligent sorting.

01 In terms of product applicability

Jumper intelligent coal and gangue sorting machine has wide adaptability and is suitable for gangue removal in raw coal preparation workshops, pre-gangue removal in coal transportation stations, gangue removal in old coal mine building renovations, coal and gangue sorting in arid and cold regions, and pre-treatment of materials in coal washing plants, etc. providing a new solution for raw coal washing and selection in arid and water-scarce areas of China 。

02 In terms of sorting particle size and capacity

Jumper intelligent coal and gangue sorting machine can perform dry selection on raw coal of +10mm-300mm and can process up to 600 tons of raw coal per hour truly achieving fast and efficient coal sorting and greatly improving production efficiency.

03 In terms of sorting cost and accuracy

Since the sorting process does not use water or medium, and no other energy is required except for electricity, the equipment operation and maintenance cost is only 2-3 yuan/ton and during the sorting process, the gangue rejection rate exceeds 98%, and the gangue content in the coal after sorting is less than 1%.

04 In terms of intelligent equipment management

Jumper intelligent coal and gangue sorting machine is highly intelligent and has one-button start-up and one-button coal selection functions. The specifically developed Jumper@Intelligent Mineral Selection Monitoring and Control System can monitor in real time key sorting indicators of the equipment and automatically issue warnings. The digital visualization of the equipment status enables unattended or minimally attended operation.

03 Speaking with Cases, Standing Out with Strength

After years of unremitting efforts, Jumper's intelligent coal and gangue sorting technology has been successfully applied to major coal-producing areas such as Shaanxi, Shanxi, Inner Mongolia, and Xinjiang, and has quickly gained customer recognition.

01 A coal mine in Shaanxi

Raw coal gangue content: 30%

Mechanical selection target achievement rate: 98%

02 A mining company in Xinjiang

Raw ore input size: +50mm-300mm

Raw coal gangue rejection rate: ≥95%

Gangue coal content (density less than 1.6g/cm³) less than 1%

Raw coal gangue removal capacity (minimum annual single-line processing capacity) ≥1.2 million tons

03 An energy company in Xinjiang

Sorting particle size: +20mm-80mm

Gangue ejection rate: ≥95%

Capacity: 100-200t/h

04 Shenyang Coal Gangue

Raw coal calorific value: 179Kcal

Clean coal yield: 10.61%

Clean coal calorific value: 1682Kcal

Clean coal recovery rate: 100%

Enrichment ratio: 9.42

05 Shanxi Mining

Raw coal calorific value: 3624Kcal

Clean coal yield: 71.26%

Clean coal calorific value: 4775Kcal

Clean coal recovery rate: 93.88%

Enrichment ratio: 1.32

Looking to the future, Jumper Technology will continue to be committed to technological innovation and market expansion, promoting the intelligent and green development of the coal washing and selection industry, and contributing to the national energy security and sustainable development.

Recommended information