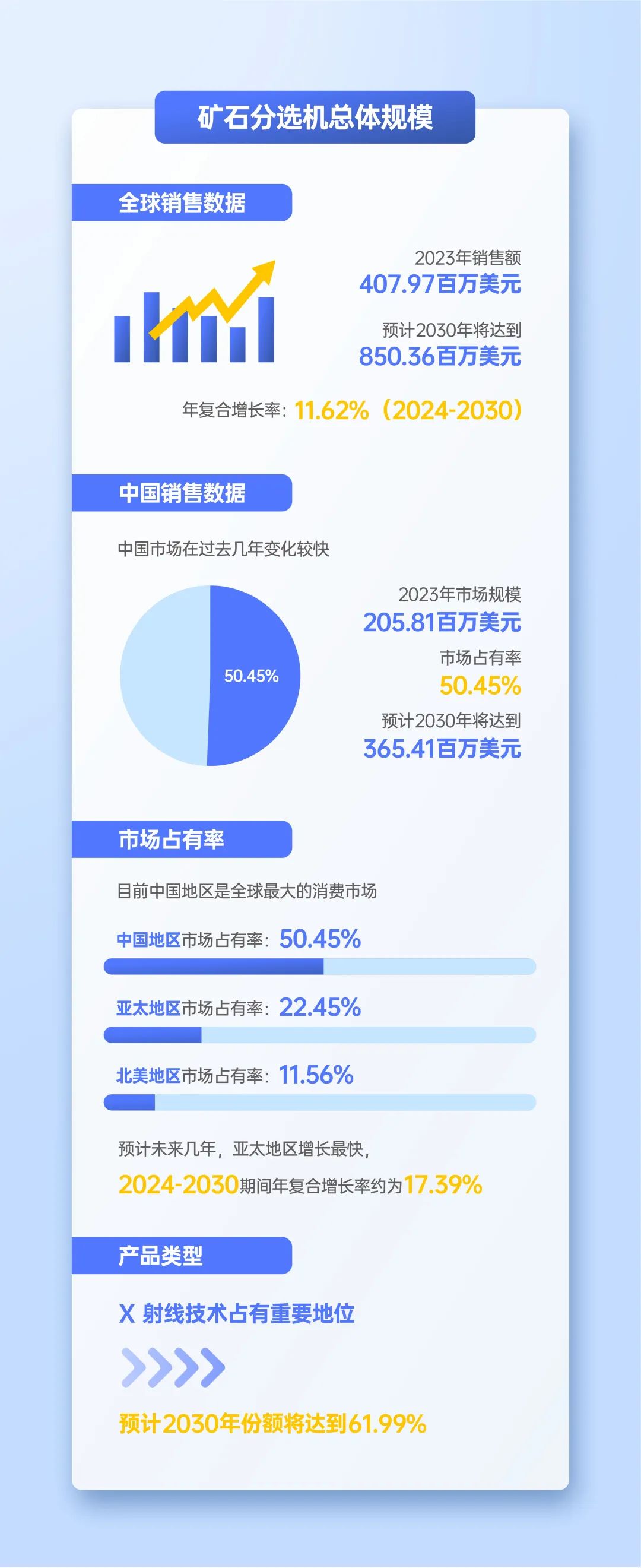

The compound annual growth rate of mineral sorter sales reached 11.62%! Intelligent sorting has great potential!

With the global demand for mineral resources continuing to grow, ore sorters, as an important part of mining production, are also expanding in market size.

(Data source: Ore sorter industry report: Global and Chinese market status and future development trends 2024)

01

16 years of technology accumulation

Jumper Technology focuses on the intelligent sorting industry

The huge market demand in the sorting industry provides broad development space for mining machinery enterprises.

Jumper Technology is the first company in China to develop radiation ore sorting technology, focusing on applying machine vision technology to empower the ore sorting field. The company's core team comes from the National University of Defense Technology and Central South University. Through self-developed high-precision signal acquisition systems and real-time AI recognition algorithms, it has successfully developed Intelligent ore sorting system, coal gangue intelligent sorting system and other series of products. The equipment can cover coal mines, non-ferrous metal mines, ferrous metal mines, non-metal mines, precious metal mines, etc. and is widely used in pre-waste disposal, waste rock beneficiation, and coal gangue removal in ore mining and selection, solving the problem of high transportation and beneficiation costs for mining enterprises.

Thanks to more than ten years of long-term accumulation and innovative genes, Jumper Technology has 60+ patents, 40+ software copyrights, 5+ self-owned trademarks R&D advantages have created technological barriers: In 2019, Jumper Technology's first intelligent ore picking system entered a lead-zinc mine in Hunan, creating the first case of intelligent ore sorting technology in lead-zinc mines in China; in 2022, Jumper Technology went abroad and won its first overseas project, The intelligent ore picking system was applied in Russia, a member of the Shanghai Cooperation Organization, and was rated as an "excellent case". In addition, Jumper Technology's equipment has been unanimously rated as internationally advanced by well-known academicians and scholars in the domestic non-ferrous metal industry, including Academician Sun Chuanyao, Academician Qiu Guan Zhou, and Professor Zhu Yimin.

02

Integrated operation system

Efficient collaboration throughout the process

In addition to technological advantages, Jumper Technology's intelligent sorting system, from the beginning of its design, has planned for integrated system operation. In terms of team configuration, A team of engineers in ore dressing technology, mine design, machinery, and electricity has been established. Integrating engineering design, manufacturing, installation, service, commissioning, and after-sales service; in terms of equipment design, it is equipped with Intelligent online monitoring and adopts Modular design Standard parts, standard construction, and at the same time Establish a remote diagnostic center Implement an effective after-sales service system to form a mature and complete service operation system.

In the future, Jumper Technology will be demand-oriented, technology-driven, and application-oriented, establishing a science and technology innovation system integrating production, education, and research, continuing to promote product quality improvement and industry standard leadership, and providing more high-quality intelligent sorting solutions for customers.

Recommended information